Basic principle of Air Leak Tester

Differential pressure method

(Pressure decay method)

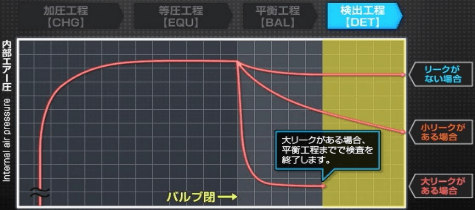

After applying air pressure into the work, the change in internal pressure is measured to evaluate for leaks.

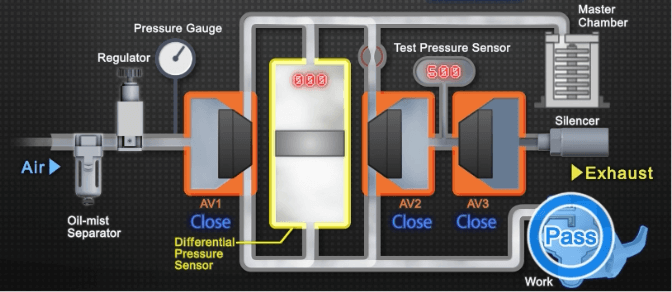

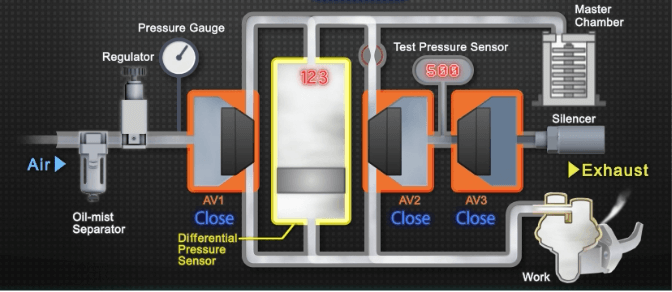

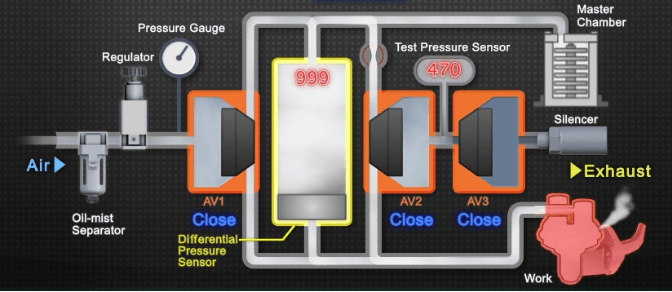

A non-leaking standard (master) is used, and is pressured at the same time as the work.

A highly sensitive differential pressure sensor detects pressure changes in the work due to leak as the difference from the pressure in the master.

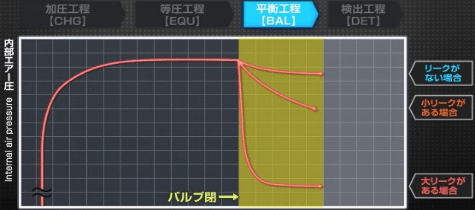

When there is no leak

When there is a small leak

When there is a large leak

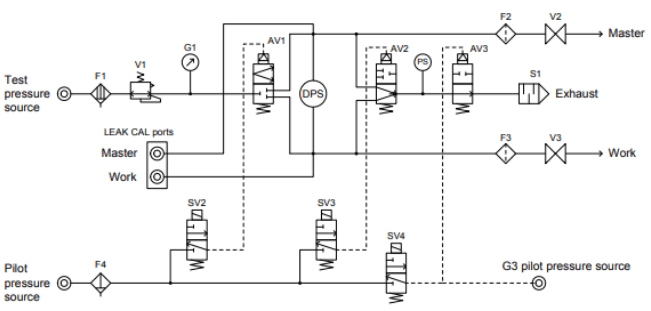

Air Leak Tester operation

(Intelligent 2 Pneumatic Circuit)

| CHG | BAL1 | BAL2 | DET | |

|---|---|---|---|---|

| AV1 (SV2) |

||||

| AV2 (SV3) |

||||

| AV3 (SV4) |

- AV1:Fill valve

- AV2:Equalization valve

- AV3:Exhaust valve

- DPS:Differential Pressure Sensor

- PS:Test Pressure Sensor

-

- CHG stage (Pressurization)

- Closes the exhaust valve (AV3) and opens the fill valve (AV1) to fill the circuit with test pressure.

-

- BAL1 stage (Equalization)

- Closes the fill valve (AV1) and stabilizes the state with the master and the work connected.

-

- BAL2 stage (Stabilization)

- Closes the Equalization valve (AV2) and stabilizes the state with the master and the work isolated from each other. Detects large leaks in this stage.

-

- DET stage (Detection)

- Detects small leaks electrically applying auto-zero. Activates Drift Compensation in this stage.

Change in internal pressure of work due to leak

During the Stabilization and Detection, the differential pressure ΔP is calculated according to the equation below after auto-zero. The leak is displayed every 0.1 seconds in units of mL/s or mL/min.

If the leak does not change and remains constant during the Detection, no additional Detection time is required.

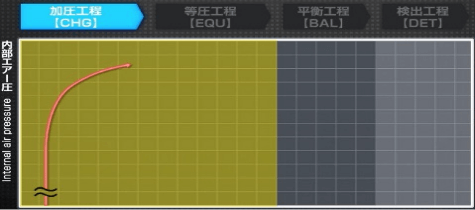

1.Pressurization

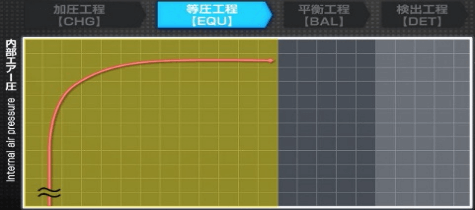

2.Equalization

3.Stabilization

4.Detection