LDS3000 / LDS3000 AQ / P3000(XL) Helium leak test

- Lightweight and compact

- High-speed test

- High sensitivity

- For system integration

- Minute leaks that cannot be detected by air leak test can be detected by using helium gas.

Basic Specs.

Leak test methods using helium gas

Vacuum method

Method of creating a vacuum inside the work

- Vacuum spray method

- Vacuum hood method

Pressurization method

Method of pressurizing helium gas inside the work

- Sniffer method

- Vacuum bell jar method

- Pressure accumulation method

- Bombing method (for works not having an opening for pressurization)

Selecting a test method

Features of each test method

To reduce running costs, helium gas mixers and helium gas recovery units are also available. Consult us.

We offer proposals based on initial and running costs.

Vacuum methods

| test method | Vacuum spray method | Vacuum hood method |

|---|---|---|

| Leak detection accuracy | 1E-09Pa・m3 /sec or more | 1E-09Pa・m3 /sec or more |

| Overall measurement | × | ○ |

| Identification of leak location | ○ | × |

| Automation | △ | ○ |

| Initial cost | ○ | △ |

| Running cost | △ | △ |

| Maintenance cost | △ | △ |

| Applicable products |  LDS3000 |

|

Pressurization method

| Test method | Vacuum bell jar method | Bombing method | Sniffer method | Pressure accumulation method |

|---|---|---|---|---|

| Leak detection accuracy | 1E-07Pa・m3 /sec or more | 1E-09Pa・m3 /sec or more | 1E-06Pa・m3 /sec or more | 1E-05Pa・m3 /sec or more |

| Overall measurement | ○ | ○ | × | ○ |

| Identification of leak location | × | × | ○ | × |

| Automation | ○ | ○ | △ | ○ |

| Initial cost | × | ○ | ○ | △ |

| Running cost | × | △ | × | × |

| Maintenance cost | × | × | △ | △ |

| Target product |  LDS3000 |

P3000(XL) |

LDS3000AQ |

|

Details of test methods

Vacuum methods

Vacuum spray method

This method detects helium that leaks into the work when the inside of the work is evacuated and helium gas is sprayed from the outside with a spray gun.

Vacuum hood method

The inside of the work is evacuated, the outside is covered with a hood, and helium gas is pressurized in the hood to detect helium gas that has leaked into the work.

Pressurization method

Sniffer method

After vacuum-pumping inside the work, helium gas is pressurized, and the helium that leaks outside is suctioned with a sniffer to detect leaks.

Vacuum bell jar method

This method detects helium leaking into the chamber by placing the work inside the chamber, pressurizing the helium gas into the work, and vacuum-pumping the chamber.

Pressure accumulation method

The work is placed in the hood, the inside of the work is evacuated, helium is pressurized, and the helium leaking into the hood is collected for a certain period of time to detect the helium (concentration) that has accumulated in the hood.

Bombing method

The work is placed in the tank and evacuated for a certain time. The inside of the tank is pressurized with helium for a certain time, and the work is removed from the tank. The work is then placed in the chamber and the chamber is evacuated to detect the helium that has entered and is present inside the work.

Leak test machine - Pressure accumulation method

Circuit configuration for pressure accumulation method

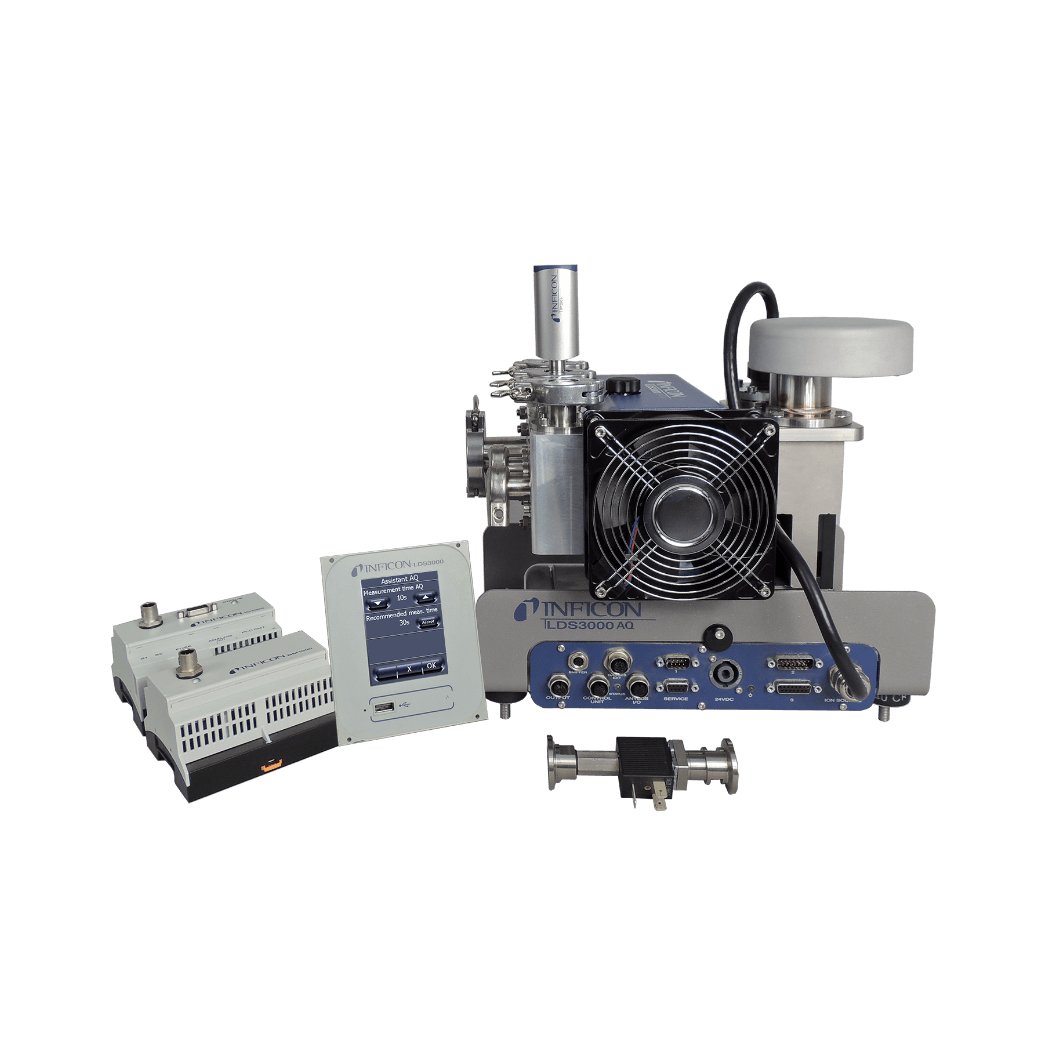

Helium Leak Detector LDS3000AQ

Mechanism of helium detection sensor

180°magnetic deflection mass spectrometer

- The helium entering the LDS3000AQ reaches the mass spectrometer by the back-diffusion by the turbo-molecular pump.

- The molecules that have reached the mass spectrometer are converted into positive (+) ions by the electrons of the filament and move in one direction by the acceleration voltage.

- The positive (+) ions separate into their orbits according to the mass of the gas (helium) when the positive ions pass through the electric field.

- Only the positive (+) ions of helium reach the ion collector and are converted into voltage signal and amplified for helium measurement.

Leak test machine Vacuum bell jar method

Circuit configuration of vacuum bell jar method

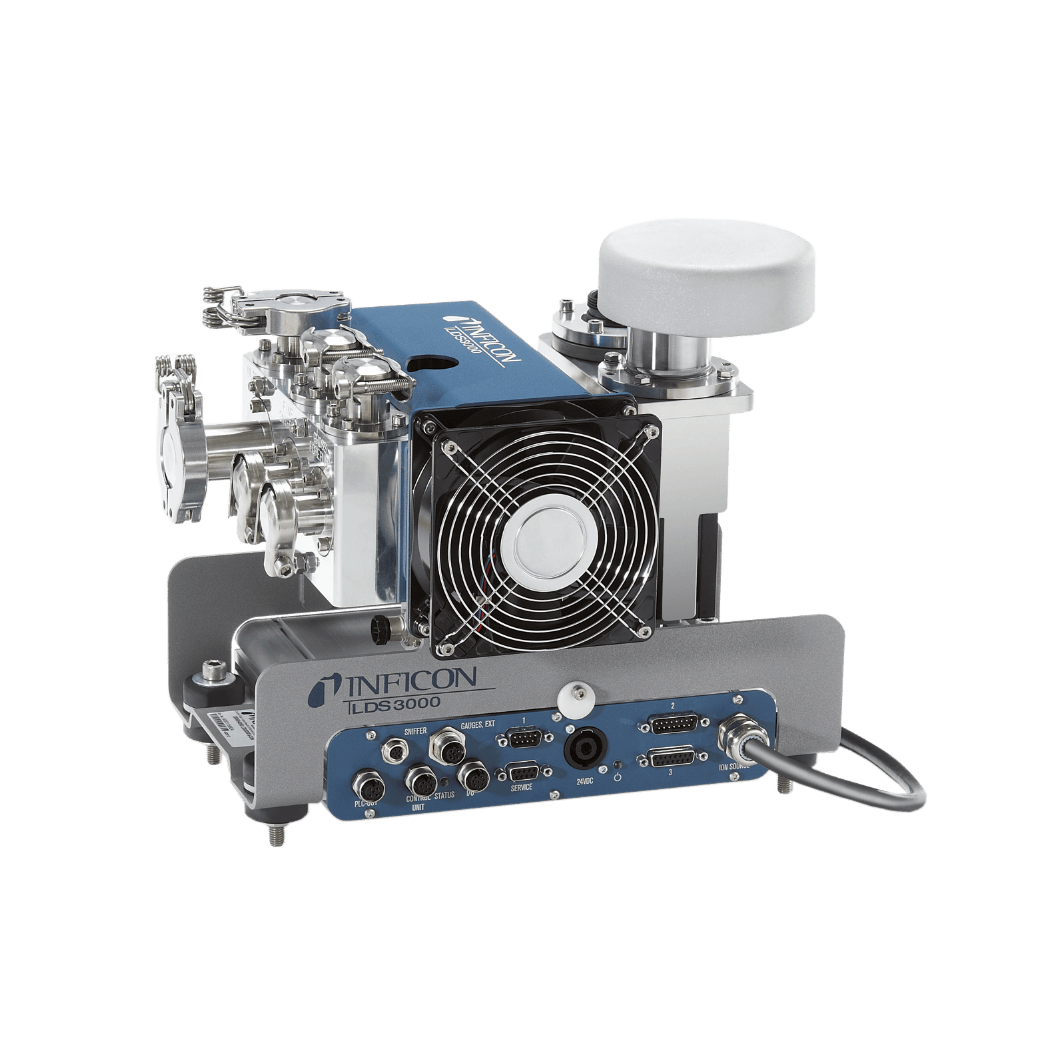

Circuit configuration of Helium Leak Detector LDS3000

Integrated leak detector is also available, with built-in valves that automatically switch each port according to the connection pressure.

Contact us for specifications.

Principle of helium detection

180° magnetic deflection mass spectrometer

- The helium entering the LDS3000 reaches the mass spectrometer by the back-diffusion by the turbo-molecular pump.

- The molecules that have reached the mass spectrometer are converted into positive (+) ions by the electrons of the filament and move in one direction by the acceleration voltage.

- The positive (+) ions separate into their orbits according to the mass of the gas (helium) when the positive ions pass through the electric field.

- Only the positive (+) ions of helium reach the ion collector and are converted into voltage signal and amplified for helium measurement.