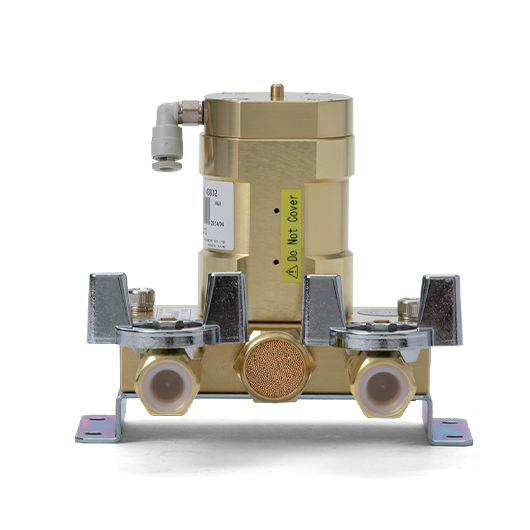

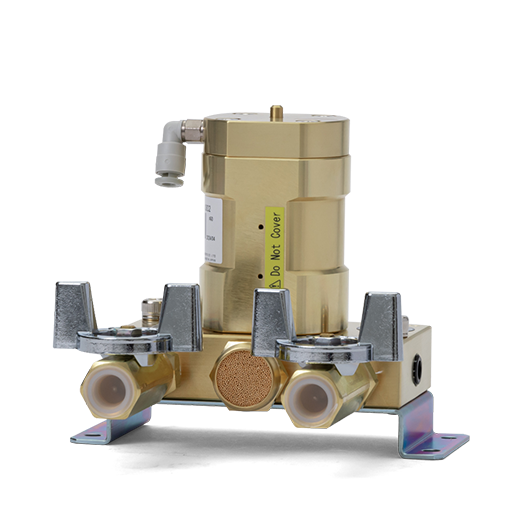

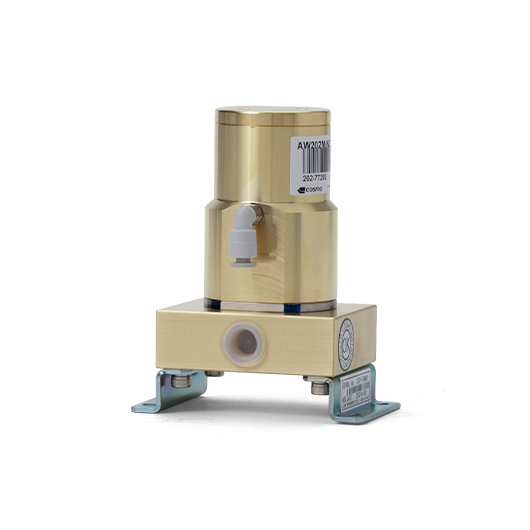

G3-M / G3-H Peripheral

- External Exhaust Valve

- Install in the middle of the piping between the leak tester and the work to exhaust air when the leak test is completed.

Prevents foreign matter such as water, oil, and dust in the works and piping from entering the leak tester, thereby preventing malfunctions and quality deterioration.

We recommend especially when performing both water dunk and air leak tests.

The External Exhaust Valve is controlled by the tester.

Basic Specs.

G3-M/G3-ME

| Maximum operating pressure | 800 kPa |

|---|---|

| Proof pressure | 1.0 MPa |

| Port size | Rc 1/4 |

| Pilot pressure | 400 to 700 kPa (supplied from the leak tester) |

| Accessories | Pilot pressure tube: Outer diameter 4 mm, Length 3 m |

| External dimensions | W116 L110 (ME: 65) H100 mm (including the mounting brackets and parts) |

| Applicable Leak Testers | Low and medium pressure leak testers applicable for External Exhaust Valve |

G3-H/G3-HE

| Maximum operating pressure | 4.9 MPa |

|---|---|

| Proof pressure | 7.5 MPa |

| Port size | Rc 1/4 |

| Pilot pressure | 400 to 700 kPa (supplied from the leak tester) |

| Accessories | Pilot pressure tube: Outer diameter 4 mm, Length 3 m |

| External dimensions | W116 L118 (HE: 65) H112 mm (including the mounting brackets and parts) |

| Applicable Leak Testers | High pressure leak testers applicable for External Exhaust Valve |

Features / Functions

Feature 1

The specially designed air-operated valve prevents leaks, small volume change, and temperature change that could cause errors in leak test.Feature 2

To prevent the malfunction of the exhaust valve due to dust, the sliding part and the detection circuit are separated from each other. (G3-M/G3-ME)Each port connecting to the work and master is equipped with a dedicated filter. (G3-M/G3-H)

Feature 3

Since large flow can be used, there is almost no effect on the pressurization time and exhaust time for the work.Feature 4

The integrated structure enables air to be exhausted simultaneously on the work and master sides.The External Exhaust Valve is controlled by the leak tester with the option of External Exhaust Valve.

Pneumatic Circuit

- The maximum length of the pilot pressure piping should be 3m.

- Otherwise, it may cause malfunction.

- Install the External Exhaust Valve horizontally, as close to the work as possible and lower than the leak tester.

Documents

- * Please fill out the form to download.