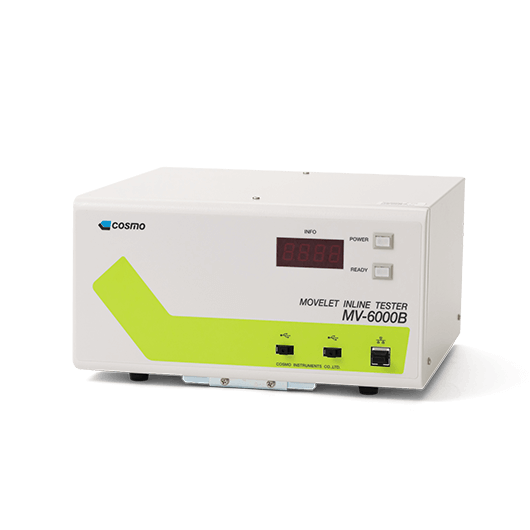

MV-6000B Movelet

- Automatic judgment

- Suitable for a wide variety of works

- The inline tester MV-6000B can register up to 99 items (channels) to handle various works.

Highly accurate inspections are realized by combining 8 types of judgment criteria.

Inspection can be automated by linking with external devices.

Basic Specs.

| Parameter | Specifications | Function specifications | Number of registered items | Up to 99 items |

|---|---|---|

| Sampling Frequency | 10000Hz / 20000Hz / 25000Hz / 40000Hz / 50000Hz / | |

| Data Acquisition Time | 10 msec to 60 sec | |

| Judgment criteria (judgment methods) |

8 types | |

| Judgment combination | Judgment criteria (judgment methods), Single judgment / Combined judgment | |

| Saving data | wav file format (The number of saved data depends on the type of sampling data) |

|

| Process status and judgment display | 7-segment display | Interface | Number of sensor input points | 1CH |

| Sensor input voltage/connector | ±5 V BNC connector | |

| USB I/F | USB-A type female: 2 | |

| COM I/F | D-SUB 9-pin (male): 1 for data (RS-232C) | |

| LAN I/F | Ethernet connector (RJ-45) | |

| CRT I/F | HD-SUB 15-pin (female) | |

| Control I/O | D-SUB 37-pin (female) NPN/PNP common | Power source | Power connector | Grounded 3P |

| Input power voltage | 100 to 240 VAC ±10% | |

| Power consumption | 80 VA (max.) | Peripheral environment | Ambient temperature | 5 to 40℃ |

| Humidity | 80%RH or less, no dew condensation | Structure | External dimensions (mm) | W300 × H160 × D280 |

| Main unit weight | Approx. 6.7 kg | |

| Option | Remote Control Box (RC-30), Multiplexer MVM-60, Sound level meter, Acceleration pick-up, LAN cable |

|

Features / Functions

Supports a variety of models

Up to 99 items can be registered.Can support production line of various works.

Handles several abnormal noises through combined judgment.

Highly accurate inspections are realized by single or combined judgment based on 8 types of judgment criteria.System update

I/O port for linking with external control equipment.Multiplexer (optional) available for switching sensors.

By linking with an impactor, a hammering test system can be constructed.

Data output (RS232C output)

Available as standard.Various ports

- VGA port: 1 for display

- USB port: 2

For connecting keyboard, mouse, and storage media (HDD, flash memory) - LAN port: 1 for connecting to Ethernet etc.

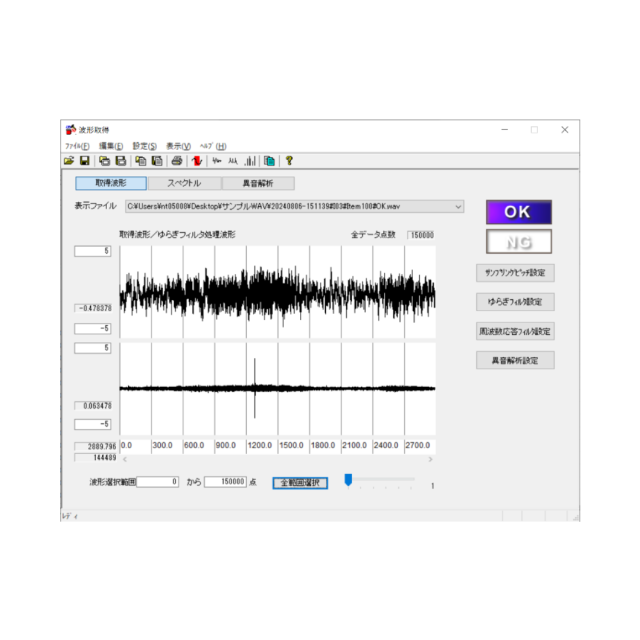

When connected to monitor Main screen

- Judgment result display (OK/NG)

- Item number, Name, Waveform (Input waveform)

- Status display

- Mode selection (automatic/manual/set)

- Details of judgment result

When connected to monitor Threshold adjustment screen

- Waveform to be analyzed

- Choose display waveform (can choose from newest 8 data)

- Threshold correction

Applications

● Automotive

Power seat / Seat rail / Air conditioner blower / Electric sunshade / Starter /Power door mirror / Power window / Wiper motor/ Engines(4-wheel and 2-wheel) / Horn / Fan / Brake butt / Car audio / Power steering / Transaxle motor● Electronic components

Fan motor / Small motors / Pump / Transformer● OA equipment

Copy machine / Fax / Printer● Electronic products

Camera (shutter sound, focus motor) / Cell phone / Air conditioner● Others

Golf club (impact sound) / Ceramic / Crack in sintered body / Building materials (cracks, peeling) / various motor mating noiseExamples of use and applications

● Seat (auto/manual) noise test

Detects abnormal sliding noise when a car seat moves back and forth or reclines.● Engine noise test

Inspects for improper assembly or missing parts in engine assembly.● Ceramic crack test

Hammering test for crack, fissure, damage, etc. in ceramic● Motor noise test

Detects abnormal motor noise.● Fan motor noise test

Detects abnormal fan motor noise.● Pump noise test

Inspects for abnormal noise during pump operation.● Transformer/inductor noise test

Detects transformer malfunctions such as buzzing, vibration, and abnormal noise.● Tunnel/concrete hammering test

Detects cracks, degradation, etc. of tunnels, concrete, mortar, etc.● Building materials hammering test

Quality inspection of building materials● Conveyor noise test

Detects abnormal conveyor noise.● Connector fitting test

Detects quasi-fitting at connection.Analysis and testing available

We conduct analysis experiments so that you can experience the benefits of the Movelet.If you can provide us with samples of good and defective works, we can collect data on site or at our company.

Feel free to contact us.

Video

Documents

- * Please fill out the form to download.